Types of Fire Pumps: Powering Efficient Suppression

Understanding Fire Pump Technologies

Introduction to Fire Pump Systems

When it comes to safeguarding lives and property, fire suppression systems play a pivotal role in ensuring rapid response and effective containment of fires. Among the crucial components of such systems are fire pumps. These pumps serve as the heart of fire protection setups, providing the necessary pressure and flow to deliver water or other fire retardants to the flames.

Contents

ToggleRole and Importance of Fire Pumps in Fire Suppression

In the firefighting realm, time is of the essence, and having the right equipment can mean the difference between containment and catastrophe. Fire pumps act as the lifeline in this critical scenario, pumping water from external sources such as tanks, rivers, or municipal water supplies into the sprinkler system or hose lines. They ensure a steady and reliable flow of water, allowing firefighters to combat blazes swiftly and effectively. Without these pumps, the efficacy of fire suppression systems would be severely compromised, leaving properties and lives vulnerable to the ravages of fire.

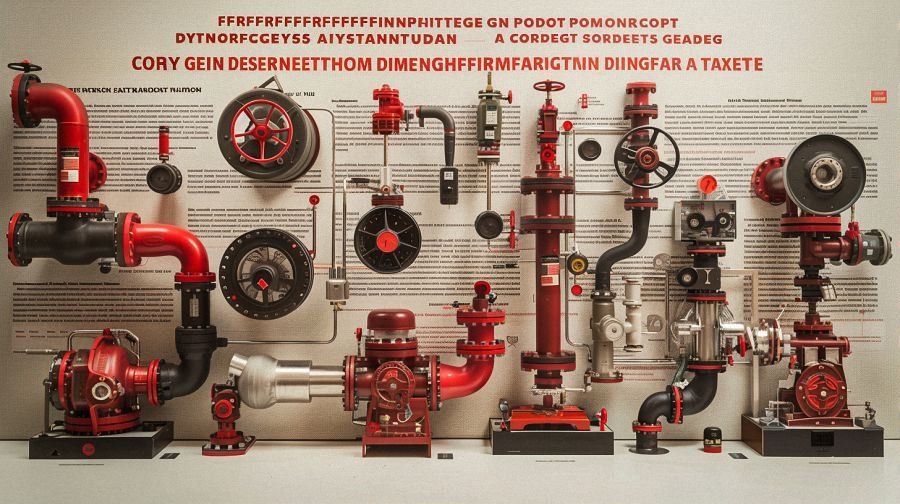

Overview of Different Fire Pump Types

In the vast landscape of fire pump technologies, various types cater to different needs and environments. Let’s delve into the diverse array of fire pumps available:

-

Centrifugal Fire Pumps: These pumps utilize centrifugal force to generate pressure and propel water towards the fire. They are commonly employed in both residential and commercial settings due to their versatility and efficiency. Centrifugal pumps come in various sizes and capacities, making them suitable for a wide range of applications, from small-scale residential installations to large industrial complexes.

-

Positive Displacement Fire Pumps: Unlike centrifugal pumps, positive displacement pumps operate by trapping a fixed amount of fluid and then displacing it into the discharge pipe. This results in a more consistent flow rate, making them ideal for high-pressure scenarios where precise control is paramount. Positive displacement pumps are often preferred in environments where water supply may be limited or fluctuating.

-

Vertical Turbine Fire Pumps: These pumps are specifically designed for installations where space is at a premium, such as high-rise buildings or underground facilities. Vertical turbine pumps feature a space-saving vertical configuration, allowing them to be installed in narrow shafts or wells while still delivering the required flow and pressure.

-

Diesel Engine-Driven Fire Pumps: In situations where electricity supply may be unreliable or unavailable, diesel engine-driven fire pumps offer a dependable alternative. These robust pumps are powered by diesel engines, ensuring continuous operation even during power outages or emergencies. They are commonly employed in remote locations or areas prone to electrical disruptions.

-

Electric Motor-Driven Fire Pumps: Electric motor-driven pumps are the go-to choice for applications where consistent power supply is available. These pumps are highly efficient and low-maintenance, making them suitable for long-term installations in facilities such as hospitals, manufacturing plants, and commercial buildings.

Understanding the nuances of each fire pump type is crucial for selecting the most suitable option based on factors such as application requirements, environmental conditions, and budget constraints. By leveraging the strengths of various pump technologies, fire protection professionals can design robust systems capable of effectively combating fires and minimizing property damage.

Centrifugal Fire Pumps: Power and Performance

Exploring Centrifugal Fire Pump Mechanisms

Centrifugal fire pumps are the workhorses of firefighting operations, harnessing the power of centrifugal force to deliver water with remarkable efficiency and speed. At the heart of these pumps lies a sophisticated mechanism designed to convert rotational energy into kinetic energy, propelling water from the source to the point of application.

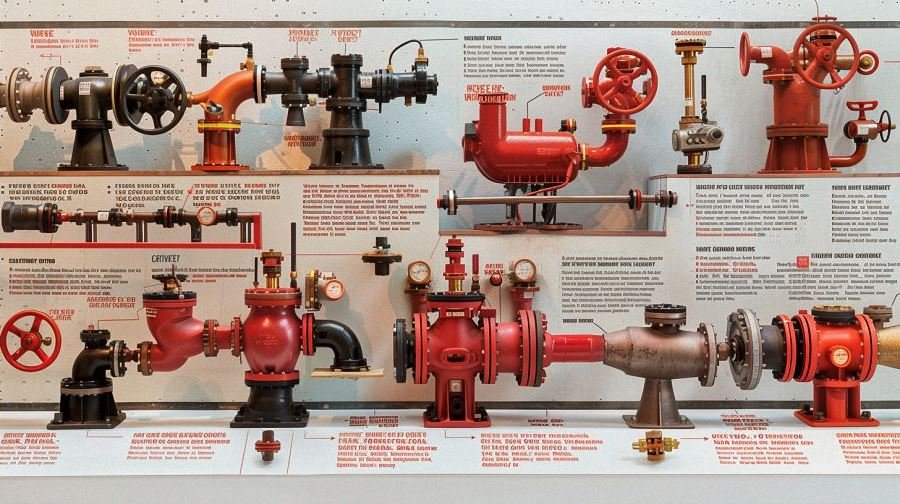

Impeller Design and Functionality

A key component of centrifugal fire pumps is the impeller—a rotating disk with curved blades that accelerates the water as it spins. The design of the impeller is crucial, as it determines the pump’s capacity to generate pressure and flow. Manufacturers employ advanced engineering principles to optimize impeller geometry, ensuring maximum efficiency and performance under varying operating conditions.

Centrifugal Pump Operation Principles

The operation of centrifugal fire pumps is rooted in the principles of fluid dynamics and rotational motion. As the impeller rotates, it creates a centrifugal force that pushes water outward, towards the edges of the pump casing. This outward motion increases the water’s velocity, creating a low-pressure zone at the center of the impeller. The water is then drawn into the pump inlet by the pressure differential, where it is accelerated once again by the rotating impeller. This cyclical process continues, generating a continuous flow of pressurized water ready for firefighting applications.

Comparative Analysis of Centrifugal Fire Pumps

Centrifugal fire pumps come in various configurations and specifications, each tailored to meet specific firefighting needs. When evaluating these pumps, several factors must be considered to ensure optimal performance and reliability.

Capacity vs. Size: Finding the Optimal Balance

One critical aspect to consider is the pump’s capacity—its ability to deliver a certain volume of water per unit of time. While larger pumps typically boast higher capacities, they also require more space and power to operate. Fire protection engineers must strike a balance between capacity and size, selecting a pump that meets the required flow rates without overwhelming the available space or infrastructure.

Efficiency and Reliability Metrics

In addition to capacity, the efficiency and reliability of centrifugal fire pumps are paramount considerations. Pump efficiency refers to the ratio of output power to input power, reflecting how effectively the pump converts energy into useful work. Reliability, on the other hand, encompasses factors such as durability, maintenance requirements, and performance consistency over time. By evaluating efficiency and reliability metrics, stakeholders can make informed decisions about which pump best suits their firefighting needs.

Case Studies: Real-world Applications of Centrifugal Fire Pumps

To illustrate the practical applications of centrifugal fire pumps, let’s examine two prominent examples from leading manufacturers:

Example: Grundfos FireFlex

Grundfos FireFlex series exemplifies the cutting-edge technology and robust performance synonymous with centrifugal fire pumps. Engineered for reliability and efficiency, FireFlex pumps boast advanced impeller designs and precision-engineered components to deliver consistent flow rates and pressure levels. These pumps have been deployed in a wide range of settings, from industrial facilities to residential complexes, showcasing their versatility and effectiveness in fire suppression scenarios.

Example: Armstrong Series 4300

Armstrong Series 4300 stands out as a hallmark of innovation and reliability in the realm of firefighting equipment. Featuring state-of-the-art impeller designs and optimized hydraulic profiles, these pumps offer unparalleled performance and efficiency. With a focus on user-friendly operation and minimal maintenance requirements, the Armstrong Series 4300 has earned a reputation for excellence in fire protection applications worldwide.

In conclusion, centrifugal fire pumps represent a cornerstone of modern firefighting technology, providing firefighters with the power and performance needed to combat blazes effectively. By understanding the underlying mechanisms, conducting comparative analyses, and exploring real-world case studies, stakeholders can make informed decisions about selecting the right centrifugal pump for their specific needs.

Vacuum Systems: Enhancing Fire Suppression Efficiency

Introduction to Vacuum Systems in Fire Protection

In the realm of fire protection, innovation is key to staying ahead of the curve. Vacuum systems have emerged as a groundbreaking technology, revolutionizing the way fires are suppressed and managed. Unlike traditional methods that rely solely on water pressure, vacuum systems harness the power of suction to enhance firefighting efficiency and effectiveness.

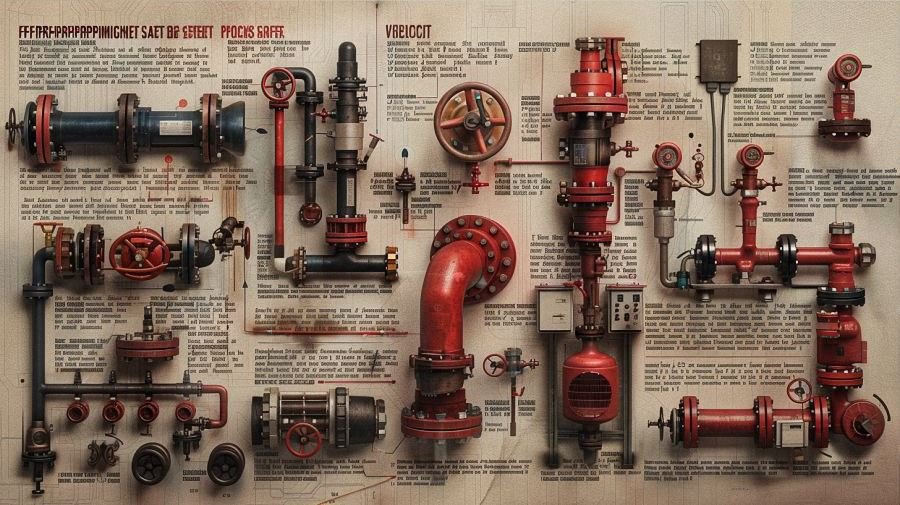

Understanding Vacuum Ejectors and Gas Jet Vacuum Apparatus

At the heart of vacuum systems lie two fundamental components: vacuum ejectors and gas jet vacuum apparatus. Vacuum ejectors utilize the Venturi effect to create a vacuum by entraining air or other gases, resulting in a rapid decrease in pressure. This vacuum is then used to draw in smoke, heat, and other fire byproducts, effectively clearing the affected area and facilitating firefighting operations. Gas jet vacuum apparatus, on the other hand, employ compressed air or steam to generate suction, offering a versatile solution for various fire suppression scenarios.

Applications of Vacuum Systems in Fire Suppression

Utilizing Vacuum Systems for Smoke Removal

Smoke inhalation poses a significant threat to both life and property during a fire incident. Vacuum systems play a crucial role in mitigating this risk by rapidly removing smoke and toxic gases from enclosed spaces. By creating negative pressure zones, these systems ensure that smoke is efficiently extracted, allowing occupants to evacuate safely and firefighters to navigate the area unimpeded.

Enhancing Water Supply in High-rise Buildings

High-rise buildings present unique challenges for firefighting due to limited water pressure and accessibility. Vacuum systems address this issue by augmenting water supply through innovative means. By utilizing vacuum technology to create suction, these systems can draw water from alternative sources such as ground-level reservoirs or dedicated storage tanks, ensuring a reliable water supply for firefighting operations in tall structures.

Advancements in Vacuum System Technology

Integration with Smart Building Management Systems

As technology continues to advance, vacuum systems are becoming increasingly integrated into smart building management systems. By leveraging IoT (Internet of Things) technology and real-time data analytics, these systems can automate fire detection, suppression, and evacuation procedures, enhancing overall safety and efficiency. Additionally, integration with building automation systems allows for seamless coordination between various fire protection measures, ensuring a comprehensive and synchronized response to fire emergencies.

Sustainable Practices: Energy-efficient Vacuum Systems

In an era of increasing environmental consciousness, sustainability has become a paramount consideration in fire protection design. Vacuum systems offer a sustainable solution by minimizing water usage and energy consumption while maximizing firefighting efficiency. By employing energy-efficient pumps, optimizing system design, and implementing water recycling measures, vacuum systems reduce their environmental footprint without compromising on performance or safety.

In conclusion, vacuum systems represent a paradigm shift in fire suppression technology, offering versatile solutions for a wide range of applications. From smoke removal to water supply enhancement, these systems continue to push the boundaries of innovation, making firefighting safer, more efficient, and more sustainable than ever before.