Types of Circulation Pumps: Maximize Heating Efficiency

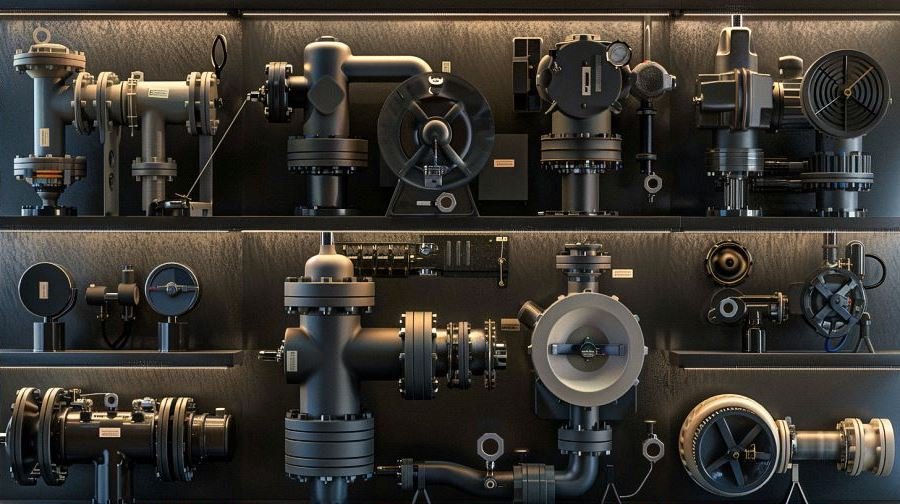

When it comes to heating systems, choosing the right circulation pump can make a significant difference in performance and efficiency. Let’s delve into the different types of circulation pumps and their applications in residential and commercial settings.

Contents

ToggleCentrifugal Pumps: Versatility and Efficiency

Centrifugal pumps are renowned for their versatility and efficiency in various heating system setups. These pumps utilize centrifugal force to move fluid through a piping system, making them ideal for applications where a continuous flow of fluid is required.

Impeller Design and Performance

One of the key components of centrifugal pumps is the impeller, which plays a crucial role in the pump’s performance. The design of the impeller affects factors such as flow rate, pressure, and efficiency. Centrifugal pumps can feature different types of impellers, including closed, semi-open, and open impellers, each with its own set of advantages depending on the specific application requirements.

Applications in Residential and Commercial Heating Systems

Centrifugal pumps find widespread use in both residential and commercial heating systems. In residential settings, they are commonly employed in boiler systems to circulate hot water through radiators or underfloor heating systems. In commercial buildings, centrifugal pumps are utilized for larger-scale heating applications such as HVAC systems, district heating networks, and industrial process heating.

Positive Displacement Pumps: Precision and Control

Positive displacement pumps offer precise control and reliability, making them suitable for demanding heating system configurations where accuracy is paramount.

Mechanism and Operation Principles

Unlike centrifugal pumps, positive displacement pumps operate by trapping a fixed volume of fluid and displacing it through the system. This mechanism allows for precise control over flow rate and pressure, making positive displacement pumps ideal for applications where consistent fluid delivery is essential.

Utilization in High-Pressure Heating Systems

Positive displacement pumps excel in high-pressure heating systems where maintaining a specific pressure level is critical for system performance and safety. These pumps are commonly used in applications such as hydronic heating systems, where precise temperature control is required to meet the demands of residential and commercial spaces.

Hybrid Pumps: Combining Strengths for Optimal Performance

Hybrid pumps offer a unique blend of the strengths of centrifugal and positive displacement technologies, providing enhanced performance and flexibility in heating system designs.

Integration of Centrifugal and Positive Displacement Technologies

Hybrid pumps integrate centrifugal and positive displacement elements to leverage the benefits of both technologies. By combining the continuous flow capabilities of centrifugal pumps with the precise control of positive displacement pumps, hybrid pumps can adapt to a wide range of heating system requirements.

Advantages in Specific Heating System Configurations

Hybrid pumps offer advantages in specific heating system configurations where traditional centrifugal or positive displacement pumps may fall short. Whether it’s balancing flow rates in multi-zone heating systems or optimizing energy efficiency in variable-speed applications, hybrid pumps provide a versatile solution for achieving optimal performance.

In conclusion, understanding the various types of circulation pumps and their unique characteristics is essential for selecting the right pump for your heating system needs. Whether you opt for centrifugal pumps, positive displacement pumps, or hybrid solutions, each type offers distinct advantages that can enhance the efficiency and effectiveness of your heating setup.

Exploring Gilex Pump Innovations

Gilex, a leading name in the heating industry, has revolutionized circulation pumps with its innovative designs and cutting-edge technology. Let’s delve into the features and advantages of Gilex centrifugal pumps, positive displacement pumps, and hybrid solutions.

2.1 Gilex Centrifugal Pumps: Efficiency Redefined

Gilex centrifugal pumps stand out for their exceptional efficiency and performance, making them a preferred choice for heating systems worldwide.

2.1.1 Unique Features and Design Advantages

Gilex centrifugal pumps incorporate advanced features and design elements that set them apart from traditional pumps. These pumps are engineered for maximum efficiency, with optimized impeller designs that ensure smooth fluid flow and minimal energy consumption. Additionally, Gilex centrifugal pumps are built to withstand harsh operating conditions, thanks to their durable construction and high-quality materials. With features such as self-priming capabilities and low maintenance requirements, Gilex centrifugal pumps offer unmatched reliability and convenience for heating system applications.

2.1.2 Case Studies Demonstrating Superior Performance

Numerous case studies highlight the superior performance of Gilex centrifugal pumps in real-world heating system scenarios. From residential heating installations to large-scale commercial projects, Gilex pumps consistently deliver exceptional results. These case studies showcase the energy efficiency, reliability, and longevity of Gilex centrifugal pumps, providing tangible evidence of their effectiveness in various applications. Customers report significant cost savings and improved system performance after switching to Gilex pumps, demonstrating the value and impact of these innovative solutions.

2.2 Gilex Positive Displacement Pumps: Precision Engineering

Gilex positive displacement pumps are renowned for their precision engineering and unmatched reliability, making them ideal for demanding heating system requirements.

2.2.1 Precision Components and Manufacturing Processes

At the heart of Gilex positive displacement pumps are precision-engineered components and meticulous manufacturing processes. These pumps are built to exacting standards, with tight tolerances and rigorous quality control measures ensuring consistent performance and durability. Gilex employs advanced technologies and materials to create positive displacement pumps that excel in even the most challenging operating conditions. With features such as variable speed control and intelligent flow management, Gilex positive displacement pumps offer unparalleled precision and control over fluid delivery in heating systems.

2.2.2 Real-world Applications and Customer Testimonials

Real-world applications of Gilex positive displacement pumps span a wide range of heating system configurations, from residential hydronic heating to industrial process applications. Customers praise the reliability, efficiency, and versatility of Gilex pumps, citing their ease of installation and low maintenance requirements. Testimonials from satisfied customers attest to the superior performance and long-term value of Gilex positive displacement pumps, underscoring their reputation as industry-leading solutions for precision fluid handling in heating systems.

2.3 Gilex Hybrid Pumps: Synergistic Solutions for Heating Systems

Gilex hybrid pumps combine the strengths of centrifugal and positive displacement technologies to provide synergistic solutions for heating system optimization.

2.3.1 Integration of Gilex Technologies for Enhanced Functionality

Gilex hybrid pumps leverage the latest advancements in centrifugal and positive displacement technologies to deliver enhanced functionality and performance. These pumps seamlessly integrate centrifugal and positive displacement elements, allowing for precise control over flow rates, pressures, and energy consumption. With intelligent control systems and adaptive algorithms, Gilex hybrid pumps optimize system efficiency while maintaining optimal performance across a wide range of operating conditions.

2.3.2 Comparative Analysis with Competing Hybrid Pump Models

Comparative analyses demonstrate the superiority of Gilex hybrid pumps compared to competing models on the market. Gilex pumps consistently outperform competitors in terms of energy efficiency, reliability, and overall performance, making them the preferred choice for heating system professionals and end-users alike. By combining the best features of centrifugal and positive displacement technologies, Gilex hybrid pumps offer unparalleled versatility and effectiveness in heating system applications, ensuring maximum comfort and efficiency for users.

Practical Considerations in Circulation Pump Selection

Selecting the right circulation pump for your heating system involves careful consideration of various factors to ensure optimal performance, efficiency, and reliability. Let’s explore the practical aspects of pump selection and how they can impact your heating system.

3.1 Performance Metrics: Efficiency, Flow Rate, and Pressure

Understanding the performance metrics of circulation pumps is crucial for selecting the right pump to meet your heating system requirements.

3.1.1 Understanding Pump Curves and Specifications

Pump curves provide valuable insights into a pump’s performance characteristics, including flow rate, head pressure, and efficiency. By analyzing pump curves, you can determine how a pump will perform under different operating conditions and select the most suitable option for your heating system. Pay close attention to specifications such as maximum flow rate, head pressure capacity, and energy efficiency ratings to ensure compatibility with your system’s needs.

3.1.2 Matching Pump Characteristics to System Requirements

It’s essential to match the characteristics of the circulation pump to the specific requirements of your heating system. Consider factors such as the size of the system, the length and diameter of the piping, and the heat load demand. A pump that is too small may struggle to provide adequate circulation, while a pump that is too large may result in unnecessary energy consumption. By carefully matching pump characteristics to system requirements, you can optimize performance and efficiency while minimizing operating costs.

3.2 Installation and Maintenance: Ease of Use and Longevity

The ease of installation and maintenance of circulation pumps can have a significant impact on the overall efficiency and longevity of your heating system.

3.2.1 Gilex Pump Installation Guidelines and Best Practices

Gilex provides comprehensive installation guidelines and best practices to ensure seamless integration of their pumps into your heating system. Follow manufacturer recommendations for proper placement, piping configuration, and electrical connections to maximize pump performance and efficiency. Additionally, consider factors such as accessibility for servicing and ease of troubleshooting when selecting a pump for your system.

3.2.2 Maintenance Protocols to Ensure Optimal Performance and Reliability

Regular maintenance is essential to ensure the optimal performance and reliability of circulation pumps. Gilex pumps are designed with longevity in mind, with features such as corrosion-resistant materials and durable components. Follow recommended maintenance protocols, such as periodic inspections, lubrication of moving parts, and cleaning of filters, to prevent issues and extend the lifespan of your pump. By investing in proper maintenance, you can avoid costly repairs and downtime while maximizing the efficiency of your heating system.

3.3 Cost-Benefit Analysis: Evaluating Investment Returns

Performing a cost-benefit analysis is crucial for evaluating the investment returns of different circulation pump options and determining the most cost-effective solution for your heating system.

3.3.1 Total Cost of Ownership Comparison Across Pump Types

Consider the total cost of ownership when comparing circulation pump options, including upfront purchase costs, installation expenses, and long-term operating costs. While high-efficiency pumps may have a higher initial price tag, they can result in significant energy savings over the lifespan of the pump, making them a more cost-effective choice in the long run. Factor in maintenance requirements and potential energy rebates or incentives to accurately assess the true cost of each pump option.

3.3.2 Assessing Energy Efficiency and Operational Savings

Energy efficiency is a key consideration when evaluating circulation pump options, as it directly impacts operating costs and environmental sustainability. Look for pumps with high Energy Star ratings and efficient motor designs to minimize energy consumption and reduce utility bills. Consider the potential operational savings associated with upgrading to a more efficient pump, including reduced energy usage, lower maintenance costs, and extended equipment lifespan. By prioritizing energy efficiency in pump selection, you can achieve significant cost savings and environmental benefits over time.