Deep Well Pump Guide: Maximize Efficiency

When it comes to ensuring a reliable supply of water, especially in areas where municipal water systems might not reach, understanding the workings of a well pump becomes essential. Well pumps serve as the lifeline for countless households, agricultural operations, and industrial facilities, drawing water from underground reservoirs to the surface. In this comprehensive guide, we delve into the intricate details of well pump technology, exploring everything from the basic principles of well operation to the nuanced characteristics that define pump performance.

Contents

ToggleHow Does a Well Work: Exploring the Basics

Groundwater Dynamics: The Science Behind Well Water

Before delving into the mechanics of well pumps, it’s crucial to grasp the fundamentals of groundwater dynamics. Picture vast underground reservoirs, where water collects in porous rock formations known as aquifers. These aquifers act as natural storage tanks, holding immense volumes of water that replenish over time through precipitation and runoff. When a well is drilled into an aquifer, it taps into this underground water source, allowing access to a continuous supply of clean, fresh water.

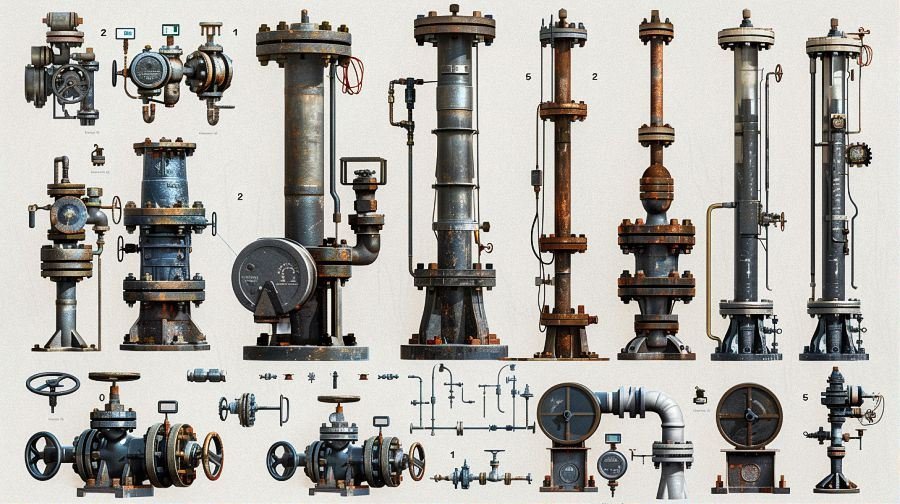

Components of a Well System: From Casing to Pump

A well system comprises several key components, each playing a vital role in the extraction and delivery of water. At its core lies the well itself, typically a cylindrical borehole drilled deep into the ground. Surrounding the well is a casing, a protective sleeve usually made of steel or PVC, which prevents the well from collapsing and keeps contaminants out. The pump, situated at the bottom of the well, serves as the heart of the system, drawing water up to the surface through a series of pipes and fittings.

Submersible Pump Technology: Unveiling the Mechanism

The Anatomy of a Submersible Pump: Motor, Impeller, and Casing

Among the various types of pumps used in well systems, submersible pumps stand out for their efficiency and reliability. Unlike traditional jet pumps, which sit above ground and draw water upward, submersible pumps are fully submerged in the well, directly pushing water to the surface. This design not only eliminates priming issues but also minimizes energy consumption by utilizing the surrounding water to cool the motor. Key components of a submersible pump include the motor, impeller, and protective casing, all meticulously engineered to withstand the harsh conditions encountered underground.

Operating Principle: Submersion, Pressure, and Water Movement

The operating principle behind submersible pumps is elegantly simple yet remarkably effective. As the pump is submerged in the well, the motor generates rotational force, which drives the impeller to spin rapidly. This spinning action creates centrifugal force, propelling water towards the surface through a series of stages or impeller blades. As water is pushed upward, pressure builds within the pump, eventually forcing it out through the discharge pipe and into the distribution system. By harnessing the power of submersion and pressure, submersible pumps offer a seamless solution for extracting water from deep wells.

Characteristics of Well Pumps: Efficiency, Durability, and Capacity

When selecting a well pump, several key characteristics come into play, each influencing its overall performance and longevity.

Capacity Considerations: Matching Pump Output to Well Depth

The capacity of a well pump refers to its ability to deliver a specific volume of water within a given time frame. Matching pump output to well depth is crucial, as deeper wells require pumps with higher lifting capacities to overcome the increased head pressure. Factors such as flow rate, pump size, and motor horsepower must be carefully evaluated to ensure optimal performance and prevent premature wear and tear.

Energy Efficiency: Evaluating Power Consumption and Performance

In today’s energy-conscious world, well pump efficiency is more important than ever. Energy-efficient pumps not only reduce electricity consumption but also minimize operating costs over the pump’s lifespan. Look for pumps with high hydraulic efficiency ratings and energy-saving features such as variable speed drives and advanced control systems. By investing in an energy-efficient pump, you can enjoy significant savings on your utility bills while minimizing your environmental footprint.

Durability Factors: Materials, Corrosion Resistance, and Maintenance Requirements

Durability is another critical aspect to consider when choosing a well pump. The harsh underground environment can take a toll on pump components, leading to premature failure if not properly addressed. Opt for pumps constructed from corrosion-resistant materials such as stainless steel or thermoplastic, which offer superior longevity and reliability. Additionally, regular maintenance and inspection are essential to ensure smooth pump operation and extend its service life. By following manufacturer recommendations and scheduling routine checks, you can prevent costly breakdowns and downtime, keeping your water supply flowing consistently.

In conclusion, understanding the intricate workings of well pumps is essential for anyone seeking to harness the power of underground water sources. By familiarizing yourself with groundwater dynamics, pump technology, and key characteristics, you can make informed decisions when selecting, installing, and maintaining a well pump system. Whether you’re a homeowner, farmer, or industrial operator, a reliable well pump is the cornerstone of a dependable water supply, ensuring peace of mind and uninterrupted access to this precious resource.

Exploring Deep Well Pumps: Solutions for Depths up to 30 Meters

In the realm of well pumps, deeper wells pose unique challenges that require specialized solutions. Whether it’s addressing the structural integrity under immense pressure or navigating extreme conditions in deep-sea applications, deep well pumps are designed to meet these demanding requirements. Let’s delve into the intricacies of deep well pump technology and explore the innovations that enable them to thrive in depths of up to 30 meters.

Deep Well Pump Design: Addressing Challenges of Depth

Construction Materials: Ensuring Structural Integrity Under Pressure

One of the primary considerations in designing deep well pumps is selecting materials that can withstand the immense pressures encountered at greater depths. Steel, particularly stainless steel, is a popular choice due to its exceptional strength and corrosion resistance. Additionally, advanced polymers such as reinforced thermoplastics offer a lightweight alternative without compromising on durability. By leveraging these robust materials, manufacturers ensure that deep well pumps maintain their structural integrity even under the most challenging conditions.

Pumping Mechanism: Adapting to Increased Head Pressure

As the depth of a well increases, so does the head pressure exerted on the pump. Traditional pump designs may struggle to cope with these heightened pressures, leading to decreased efficiency and reliability. Deep well pumps employ innovative pumping mechanisms that are specifically engineered to adapt to these increased pressures. Multi-stage impellers, for example, allow the pump to generate higher levels of pressure while maintaining optimal flow rates. Additionally, variable frequency drives (VFDs) provide precise control over pump speed, enabling efficient operation across a wide range of depths.

Deep Sea Well Pumps: Navigating Extreme Conditions

Submersible Systems for Deep Sea Applications: Challenges and Solutions

In deep-sea applications, such as offshore oil platforms and underwater research facilities, well pumps face a myriad of challenges, including corrosive saltwater, extreme temperatures, and high hydrostatic pressures. Submersible pump systems offer a viable solution by housing the pump and motor in a watertight enclosure, protecting them from the harsh marine environment. Specialized coatings and materials, such as epoxy resin and titanium, enhance corrosion resistance, ensuring long-term reliability in saltwater environments.

Pressure Management: Coping with High Pressure Environments

Deep-sea well pumps must contend with exceptionally high hydrostatic pressures, which can exceed hundreds or even thousands of pounds per square inch (psi). To cope with these extreme conditions, pumps incorporate reinforced casings and seals designed to withstand the immense forces exerted by the surrounding water. Additionally, pressure compensating devices, such as bladder accumulators, help maintain optimal pump performance by counteracting fluctuations in pressure and ensuring consistent water delivery.

Performance Evaluation: Assessing Efficiency and Reliability

Testing Deep Well Pumps: Benchmarks for Performance and Longevity

Before deployment in real-world applications, deep well pumps undergo rigorous testing to evaluate their performance and reliability. Benchtop tests assess key metrics such as flow rate, head pressure, and energy efficiency, providing valuable insights into pump capabilities under varying conditions. Field trials further validate pump performance in actual operating environments, allowing manufacturers to fine-tune designs and address any potential issues before market release.

User Feedback Analysis: Real-World Experiences and Recommendations

User feedback plays a crucial role in shaping the evolution of deep well pump technology. By soliciting input from end-users and industry professionals, manufacturers gain valuable insights into real-world performance, reliability, and usability. This feedback loop enables continuous improvement, driving innovation and ensuring that deep well pumps meet the evolving needs of customers across diverse applications and environments.

In conclusion, deep well pumps represent the pinnacle of pump technology, capable of thriving in the most challenging of environments. From addressing structural integrity under pressure to navigating extreme conditions in deep-sea applications, these innovative solutions offer reliable water supply solutions for depths of up to 30 meters and beyond. With a focus on durability, efficiency, and performance, deep well pumps stand ready to meet the demands of today’s most demanding water extraction tasks.

Selecting the Right Deep Well Pump for Your Needs

Choosing the perfect deep well pump involves careful consideration of various factors to ensure optimal performance and reliability. From evaluating well depth to comparing pump models and addressing installation and maintenance requirements, this guide provides valuable insights into selecting the ideal pump for your specific needs.

Factors Influencing Pump Selection: Depth, Flow Rate, and Water Quality

Evaluating Well Depth: Matching Pump Capabilities to Water Source

The depth of your well is a critical factor that directly impacts the selection of a suitable pump. Deeper wells require pumps with higher lifting capacities to overcome the increased head pressure. Before making a decision, it’s essential to accurately measure the depth of your well and select a pump that can efficiently lift water from that depth without overworking the motor or compromising performance.

Flow Rate Requirements: Balancing Water Demand with Pump Capacity

Determining the required flow rate of your deep well pump involves assessing your household or operational water needs. Factors such as the number of occupants, water usage patterns, and irrigation requirements all influence the desired flow rate. It’s essential to choose a pump that can deliver sufficient water to meet demand while maintaining consistent pressure and flow throughout the distribution system.

Water Quality Considerations: Filtering, Purification, and Treatment Needs

Water quality plays a significant role in pump selection, particularly in areas with high levels of sediment, minerals, or contaminants. Depending on your specific water quality parameters, you may need to invest in additional filtration, purification, or treatment systems to ensure safe and potable water. When selecting a pump, consider its compatibility with existing water treatment infrastructure and any additional features required to maintain water quality standards.

Comparing Deep Well Pump Models: Performance, Features, and Cost

Product Comparison: Highlighting Key Specifications and Features

Comparing deep well pump models involves evaluating a range of specifications and features to determine the best fit for your needs. Key factors to consider include pump capacity, motor horsepower, efficiency ratings, and construction materials. Additionally, look for features such as built-in protection mechanisms, variable speed drives, and compatibility with remote monitoring systems. By carefully comparing pump models, you can identify the one that offers the optimal balance of performance, reliability, and value.

Cost-Benefit Analysis: Balancing Initial Investment with Long-Term Savings

While upfront cost is a significant consideration when purchasing a deep well pump, it’s essential to look beyond the initial investment and consider long-term savings and benefits. Energy-efficient pumps may command a higher price tag upfront but offer substantial savings on electricity bills over their lifespan. Similarly, pumps constructed from durable materials may require less frequent maintenance and replacement, resulting in lower overall operating costs. By conducting a thorough cost-benefit analysis, you can make an informed decision that maximizes value and ROI.

Installation and Maintenance: Ensuring Proper Setup and Care

Installation Procedures: Guidelines for Safe and Effective Setup

Proper installation is crucial to the performance and longevity of your deep well pump. Follow manufacturer guidelines and industry best practices to ensure safe and effective setup. This includes selecting an appropriate location for the pump, securing it in place with proper anchoring, and correctly sizing and connecting piping and fittings. Additionally, ensure that electrical connections are installed by a qualified electrician and comply with all relevant codes and regulations.

Maintenance Best Practices: Tips for Prolonging Pump Lifespan and Efficiency

Regular maintenance is essential to keep your deep well pump operating at peak performance and prevent costly breakdowns. Develop a maintenance schedule that includes tasks such as inspecting and cleaning pump components, lubricating moving parts, testing pressure and flow rates, and monitoring motor performance. Additionally, be proactive in addressing any signs of wear or damage, and promptly repair or replace worn-out parts to prevent further damage and ensure continued reliability.

In conclusion, selecting the right deep well pump requires careful consideration of various factors, including well depth, flow rate requirements, water quality considerations, pump performance, features, and cost. By taking the time to evaluate these factors and follow best practices for installation and maintenance, you can ensure optimal performance, longevity, and reliability from your deep well pump for years to come.